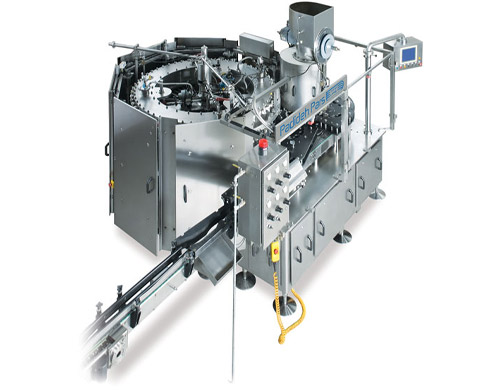

Filling and Capping Machine, Model: 400

Glass Bottle

– Filling CSD Beverages

– Cold Filling

– Applying Metal Crown Corks

8,000 up to 20,000 bottles/h

MONOBLOCK-GLASS machine is designed to bottle carbonated beverages in glass bottles ranging from 250 cc up to 1000 cc. It has 56 filling nozzles and 14 pressing heads.

Product: CSD

Bottle Type: Glass

Bottle Size: from 250 cc up to 1000 cc

Cap Type: Metal Crown Corks

This machine has the following features:

1.Filling system

The bottles arriving from the rinsing section are transported with star-wheel in to the filling section. Once the bottle is lifted against filling valve and sealing is achieved, then the valve is opened and the filling process begins whilst air inside the bottle is released through the air return tube. The Isobaric filling technology (Counter Pressure) is used for bottling carbonated products. The filling operation is carried out under CO2 pressure and product temperature 2- 4 degrees Celsius.

2.Crown capping system

The crowner consists of two sections: the crown hopper, which holds and selects the crown and the crowing section which crimps the crown in the place on the bottles.

3.Motion system

The machine is equipped with helical polyamide gears.

4.Change parts

Change parts made of special anti-corrosion polymer.