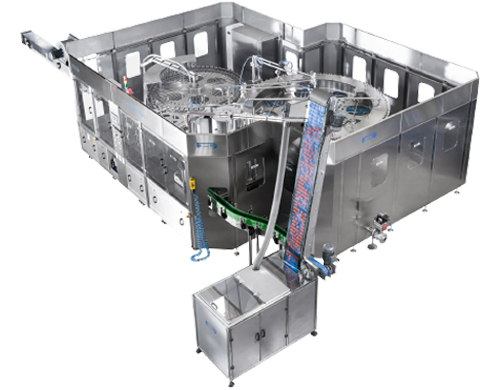

Rinsing, Filling and Capping Machine

PET & HDPE Bottles

– Filling non-CSD and CSD Beverages

– Cold and Hot Filling

– Applying Plastic Screw Cap

5,000 up to 24,000 bottles/h

TRIBLOCK-PET machines (Rinsing, Filling and Capping) have been developed for bottling carbonated and non-carbonated soft drinks and other edible liquids in PET and HDPE bottles ranging from 200 cc up to 1500 cc.

Padideh Pars company presents different size of TRIBLOCK-PET machines with “Neck Handling System” ranging from 30,45,70 and 80 filling valves and capacity from 5,000 up to 24,000 bottles per hour.

Product: CSD, Non-CSD, Dairy , Edible Liquids

Bottle Type: PET & HDPE

Bottle Size: from 200 cc up to 1500 cc

Cap Type: Plastic Screw Cap

| Model | Rinsing Nozzles | Filling valves | Capping Heads |

| 630 | 30 | 30 | 10 |

| 645 | 30 | 45 | 10 |

| 670 | 50 | 70 | 10 |

| 680 | 60 | 80 | 10 |

The machine has following features:

1.Bottle Infeed System

Empty bottles are transferred through the air conveyor into filling machine. Neck to neck handling system is offered for both PET and HDPE bottles, where the bottles are conveyed on their neck and requiring no height adjustment.

2.Rinsing System

Inside of bottles are cleaned by spraying water in a single-phase rinsing process. Empty bottles are transferred into the rotary rinsing section by a star-wheel. The bottles are hold from their neck by means of special grippers and turned upside down (180°). After the water is sprayed into the bottle for a certain period of time, the bottle goes upside down for a little more while to drain and then returns to its normal position.

3.Filling System

4.Capping system

The machine is equipped with stainless steel, magnetic and Pick&Place capping heads to apply plastic screw caps.